![]()

![]()

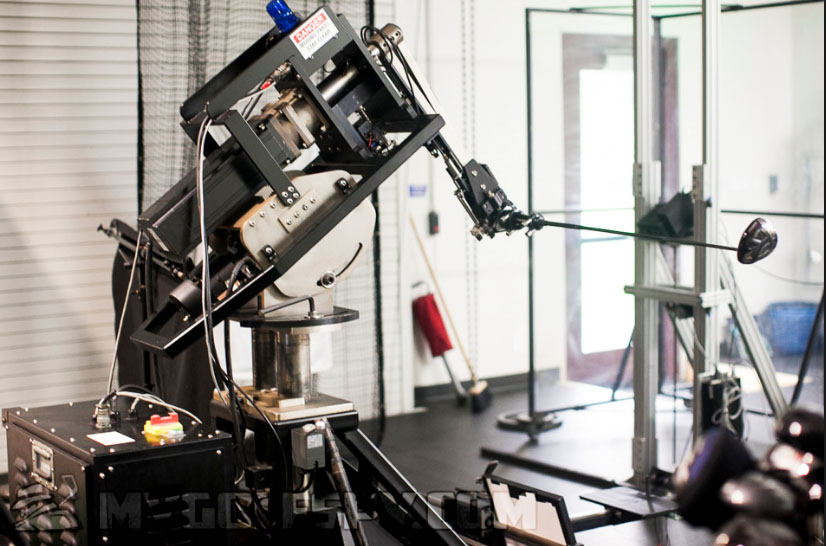

GSA Golf develop and manufacture the world's most affordable, yet most advanced and comprehensive

hi-speed camera golf simulator tracking systems on the market today

Technical News

![]()

System Updates & Development News

GSA Golf daily updates and news

Hi! I'm Martin Paul Gardiner

Electronics and software development engineer and founder of GSA Golf

Regularly check out my tech news page for all our latest developments and free updates

GSA Golf tech news is updated almost daily!

so make sure to check in for all the latest updates and news regularly

If you have any questions

please feel free to contact me personally anytime from M to F - 12noon to 3pm US ET via e-mail at

Please Note: We're closed on weekends and all US national holidays

If you are contacting us on the weekends or on national holidays,

then we'll make best effort to get back to you within 24 hours of the next working day.

![]()

Did you get a response to your e-mail?

We get really busy at times and e-mail responses can be late or even forgotten at times.

Please remind us again if you didn't get a response to your e-mail.

![]()

![]()

GSA Golf Control Panel (CP) Updates

CP 64 update 10.3.5.9

![]()

June 27 11:45 am

Click the above button to download the latest CP 64 update.

This is a fast download and installation,

suitable for most users that have done updates and initial installations within the last year or so.

![]()

Click the above button to install the new 64 bit full version of the CP

![]()

Don't forget to run the download after it's downloaded!

A number of customers don't realize that a CP update is a dual process

i.e first download and then run the download

Note: updates are only for previous full installations.

You cannot run updated without having first installed the full base version

if you are a new user:

Click the large red button below to install the full version first if you are a new user.

Only download and run the update after downloading and installing the full version if you are a new user

How to install the CP (Control Panel) full version and updates

Try it before you buy it

GSA Golf Control Panel Full version download

The full version VisTrak software can be used to evaluate the system with real time image processing

from sample shot videos sent to us from customers.

Download includes sample shot videos of the SCX, EVi and LX2

![]()

Technical Support

![]()

Please note that the prices published on this website

are pre-Trump tariff prices.

Prices may well increase soon.

e.g

Should the Trump 50% tariffs for EU products kick in ,

then the price of the ProTee VX will increase from $6,499 to $8,499

Should the Trump tariffs for Chinese products kick in ,

then the price of GSA Golf camera systems (the cameras are made in China) will increase by at least $500

![]()

![]()

June 27 11:45 am

CP update 10.3.5.9

New "Check Ball Strike Frame" option

As it was noticed that the ball strike frame wasn't always being detected correctely, I added this new option that checks it.

June 26 1:00 pm

CP update 10.3.5.8

Improved ball spin detection for EV and LX systems

Fix: CP not detecting club when GSpro selects a Hybrid 4 club

June 24 12:00 pm

CP update 10.3.5.7

New brighter spin video ball images

New Sample putt video

Chipping mode delay frames increased to 8

June 23 11:10 am

CP update 10.3.5.5

Fix: CP not detecting Hybrid club slection in GSpro

Coming later this week:

New openCV edge detection methods that enhance the ball spin markings and club faces.

The later should eliminate the requirement to apply club white strips to the clubs.

June 22 11:39 am

CP update 10.3.5.4

New: You can now switch on Chipping Mode with the C key even though the system may be in AutoChipping mode.

June 22 7:58 am

CP update 10.3.5.3

Error in ball speed frame spacing fixed

June 21 3:38 pm

CP update 10.3.5.3

Improved shot replay controls

June 21 12:38 pm

CP update 10.3.5.1

Update for EV1 and LX users

June 21 8:56 am

CP update 10.3.5.0

GSpro distance to pin issue

As GSpro reports multiple ball distances to pin with every shot via the API, it has been difficult to determine the correct current distance.

This CP version compares the reported distances with previous distances reported and chooses the distance that is new.

Note that the distance to pin is used to switch the CP to chipping mode. If the distance is incorrect then the CP can get stuck in Chipping mode.

June 20 12:56 pm

CP update 10.3.4.9

Nice new feature: Post shot video playback now only showing relevant frames so that blank frames are removed.

Updates for EVi users and Chipping mode users

June 19 4:23 pm

CP update 10.3.4.6

A number of smaller errors fixed

June 18 1:23 pm

CP update 10.3.4.5

Issue with GSpro not reporting correct distance ball is from pin resolved

Auto distances that the chipping mode kicks in is now max 40 yards from pin and Min 4 yards from pin.

June 16 10:00 am

New lower price for the SCX Lite

$ 1,799.00

Click above image to read more ...

New curved screen frame assembly instructions

Click above image to read more ...

June 15 11:23 am

CP update 10.3.4.3

A number of smaller issues resolved

June 14 2:45 pm

New low priced SCX IR casings available for DIY customers

$ 499.00

More instructions and tips on how to build a curved screen

Click above image to read more...

June 13 1:00 pm

CP update 10.3.4.2

Fix: CP - GSpro not always reporting correct distances from pin

This problem can cause the CP to get stuck in Chipping Mode after a hole finish

New: If you have selected a number of clubs to be auto chipping mode clubs but don't want to use them,

you can now switch them OFF without having to de-assign them.

June 12 3:00 pm

CP update 10.3.4.0

New Putting and Chipping modes that show club slow motion shot video of club approaching ball, at impact and follow through.

Click the Permit Putting / Chipping option ON to activate in the Setup Panel

Click the Auto Chipping Mode option ON in the CP's main panel

Set the distance the ball should be from the pin so that chipping mode is automatically activated when the ball distance from the pin is less than that.

You can also manually activate Chipping mode by pressing the C key

or selecting a particular club and assigning it to be an Auto Chipping Mode club so that every time this club is selected, the system switches to Chipping mode.

You can select multiple clubs to be a Chipping mode club too by selecting the club and clicking the Chipping Mode club button.

Slow motion video putting mode automatically kicks in when a putter club is selected (either manually or via the game software)

To see a sample of how the new chipping mode video shot replay looks, load the sample videos and select Video 5.

June 10 4:56 Pm

GSA Golf now offering the new Ernest Sports Launch Monitors

Click above image to read more...

GSA Golf now offering the new Mevo Plus Launch Monitors too

Click above image to read more...

GSA Golf is also currently applying for dealership rights with Foresight Sports and Uneekor systems.

-

-

June 9 12:35 Pm

CP 64 update 10.3.3.8

Fix: Very occasional incorrect VLA being calculated

June 9 2:15 pm

GSA Golf business news. GSA Golf on Amazon coming soon

Well, I've managed to get through all the Amazon requirements to be an official Amazon reseller now.

GSA Golf is the official brand name on Amazon now too.

Amazon compliant photos of the main GSA Golf launch monitors have been completed and I expect to be going live on Amazon by the weekend.

Many more GSA Golf products will also available on Amazon including Curved Screens

June 8 6:44 pm

New Launch Monitor hi-speed camera package

Available on Amazon soon

June 6 4:12 pm

GSA Golf business news. GSA Golf on Amazon coming soon

Most of this coming week will spent on setting up the GSA Golf presence on Amazon.

As Amazon requires real photos of the products, I'll be spending this weekend with real product photo shoots.

Many more photos of all the SCX models to come.

The great thing about selling on Amazon is that you get a massive amount of product exposure at a very low price.

Compared to Google's Ad Words, where you can spend $10's of thousands a month on a pay per click basis, Amazon don't charge for any clicks.

June 5 2:35 pm

GSA Golf business news. Surge in sales

I'm not quite sure why I'm getting a surge in sales these days (especially as it's Summer which is normally a dead period) but I'm not complaining about.

Contributing factors could be my increased organic ranking on Google (page 1) and the fact that I'm selling on eBay now.

If it's due to my eBay listings, then God knows what's going to happen when I launch my products on Amazon.

I'm actually a tad worried about that because I could get overwhelmed with orders and won't be able to keep up with them all.

Anyway, we'll see. Preferring a quite life, I don't want to get too big.

June 4 10:35 am

CP 64 update 10.3.3.7

Important Fix: Shot Video files not storing the users setup correctly.

The stored user setup settings in the shot video files are used by us to assist user support and see what settings the user has made.

In addition, this error could have caused setup settings to be overwritten with the incorrectly stored settings in the video files when loading previous shot videos.

June 1 4:30 pm

First production run photos of the new SCX Lite

May 30 3:00 pm

New selection of auto golf ball tee-up and ball return systems

GSA Golf Ball return ramp

Click above image to read more...

May 30 12:30 pm

CP 64 update 10.3.3.6

Possible putting issue resolved

May 29 1:30 pm

CP 64 update 10.3.3.5

Numerous smaller modifications and updates

New customer camera registrations

Improved spin detection when using TM PIX balls

May 28 9:00 am

CP 64 update 10.3.3.4

Fix: CP API not sending spin axis parameter

New CP API update required for the missing spin axis parameter

More spin detection improvements when using a side mounted camera to measure ball spin using TM PIX balls

May 27 12:00 pm

CP 64 update 10.3.3.3

More spin detection improvements when using a side mounted camera to measure ball spin using TM PIX balls

May 25 1:25 pm

New improved LX2 top camera casing

New LX2 lower pricing - now just $1,999

New LX2 sub-system available for $999 - just add Amazon cameras and save $400

May 24 1:35 pm

CP 64 update 10.3.3.1

Numerous smaller modifications and updates

New customer camera registrations

Improved spin detection

May 23 3:35 pm

GSA Golf business news.

Well, that made my day.

I must be doing something right I guess.

May 22 6:55 pm

New Eagle Lite

May 22 12:35 pm

CP 64 update 10.3.3.0

Numerous smaller modifications and updates

Spin adjust slider bar now also in the Camera panels

Improved spin detection

May 21 11:05 am

New SCX IR Sub-system

Just add the 1 or 2 Hauteng Vision 1500 fps cameras and extension cables

Available on Amazon for around $300 each

$ 899.00

This product is designed to sell on Amazon where the buyer can simply add the Amazon Hauteng Vision cameras to their Amazon cart if they wish.

The advantage for the purchaser is that they save $400 on the full price of the SCX IR Lite

May 1912:05 pm

CP 64 update 10.3.2.8

1. Rule that camera shutter speed (exposure time) be below 150 us in order to measure ball spin has been removed

2. If the system lock is switched ON, then a flashing message indicating this will be displayed.

May 18 8:00 am

New SCX IR Lite

The new SCX IR Lite replaces the SCX IR Track.

System functions as the regular SCX and features 24 hi-intensity narrow beam IR LED lights

May 16 12:05 pm

CP 64 update 10.3.2.7

1. Improved method of ball spin adjustment

you can now use the keyboard's left and right arrow keys instead of the mouse over the slider bars

2. Option to use the average of 3 spin rate readings over multiple frames or just a single reading

May 15 12:05 pm

CP 64 update 10.3.2.6

Improved 1: Ball detection when balls have large markings on them (i.e. TM Pix balls)

Improved 2: Ball spin detection when balls have large markings on them (i.e. TM Pix balls)

May 9 4:00 pm

New lower price for the LX2: now just $1,999

New selection of GSA Golf all-inclusive hi-end simulators

Prices from $20,000

Click above images to read more...

May 8 1:40 pm

New selection of lower cost simulators

Click above image to read more...

May 5 11:40 am

CP 64 update 10.3.2.5

Fix: Video replay rate too slow

New: New sample SCX Putting video

GSAgolf.com domain and email now up and running again

May 4 5:40 pm

GSAgolf.net domain now up and running

GSAGolf.co coming later tomorrow

May 4 12:40 pm

CP 64 update 10.3.2.4

New customer camera registrations

More details on how to install curved screens

Click above image to read more...

April 28 1:20 pm

New low cost ($399) curved screen track

For those that have a dedicated golf simulator room, you can now simply attach a curved screen

to the curved track that is mounted on the ceiling.

This method eliminates the requirement to make up a frame.

April 27 2:20 pm

Curved screens now with adjustable curvature feature

New "A" tube variable angle connector allows you to

adjust the amount of curvature your curved screen willl have

April 24 3:20 pm

The new GSA Golf reseller price list now available

We're currently sending these out to over a hundred resellers world-wide.

If you're a golf simulator reseller and didn't receive your copy yet, drop us a line and we'll send it to you.

April 23 1:00 pm

New lower priced SCX Lite cased

April 21 2:30 pm

We now have a new large selection of full system packages

Click above image to read more ...

In association with Carl's screens and enclosures, we're now also offering the new Carl's curved screen enclosures

Click above to read more about the new Carl's curved screens and enclosures

New GSA Golf curved screens and enclosures now available as kits

Click above to read more about the new GSA Golf curved screens and enclosures

April 16 4:15 pm

Trump's 145% tariffs on China soon to cause Golf Simulator related products prices to rise.

Not just golf simulator products of course. All prices for all products will rise.

My personal opinion:

As both Trump and China won't be backing down anytime soon, I predict the following worst case scenario:

China will either invade Taiwan or institute a total blockade (sea and air) of all electronic exports from Taiwan to the US.

This will cripple the US economy of course as nearly all cars, planes and all other electronic related manufacturing depend on chips from Taiwan.

Should be interesting to see how this plays out. Especially if China and Russia join forces against the US.

I wouldn't be surprised that there would be major military stand offs in a scenario like this, should this indeed be the case.

Looks like we're in for some pretty rocky times. So hold on to your hats!

April 16 11:30 am

CP 64 update 10.3.2.3

ROI ball position in LX and EVi Vcam cameras set higher to allow for larger ball image sizes

April 15 3:30 pm

VisTrak LX2 Stand replaces the regular LX2

Testing today revealed that the advantages of new LX2 Stand far exceeds any advantages the regular LX2 may have.

As such, the regular LX2 has been discontinued and replaced by the LX2 Stand

For those that find that the top mounted camera and light blocks too much view of the ball on the mat with the regular LX2,

you can now opt for the new LX2 Stand version of the LX2.

In addition to the stand, the LX2 Stand features more powerful 24 LED IR narrow beam lighting

and the camera and lighting is aimed directly down onto the ball on the mat and not at an angle like the regular LX2.

This eliminates skewed views of the ball HLA (path) that have to be software corrected.

i.e. what you see is the exact ball path HLA of the shot.

The LX2 Stand is essentially a portable EVi system that doesn't require that the top camera be mounted on the ceiling.

April 13 12:30 pm

CP 64 update 10.3.2.2

New: Ball speed / Club Speed Smash now displayed in all video and camera panels

Fix: Fluctuating side spin after re-calculating shot video

New: Relative club face to club path angle now displayed in all video and camera panels

Note: When the system is unable to determine side spin from marked balls,

then side spin is calculated from the relative club face angle to path and not just from the face angle itself.

Shot shaping with VisTrak systems

Examples:

1.Draw

If club path is 10 degrees in-to-out and face angle is 5 degrees open, then relative club face angle is -5 degrees closed

which results in a negative side spin and the ball will curve back left after starting off right (i.e. a draw)

2. Pull draw

If club path is 10 degrees in-to-out and face angle is -5 degrees closed, then relative club face angle is -15 degrees closed

which results in a negative side spin and the ball will curve left after starting off left (i.e. a pull-draw)

3. Push

If club path is 5 degrees in-to-out and face angle is 5 degrees open, then relative club face angle is zero degrees

which results in a zero side spin and the ball shot is a straight push right

3. Fade

If club path is 0 degrees and face angle is 5 degrees open, then relative club face angle is +5 degrees

which results in a positive side spin and the ball shot is a curve to the right after starting out straight

3. Push Fade

If club path is 10 degrees in-to-out and face angle is 15 degrees open, then relative club face angle is +5 degrees

which results in a positive side spin and the ball shot is a curve to the right after starting out right

April 11 10:30 am

CP 64 update 10.3.2.1

Fix: Ball spin data not being stored in shot videos correctly

Fix: Relative club face to club path angle no being calculated correctly

New: Improved side spin calculations

April 8 2:40 pm

CP 64 update 10.3.1.8

Fix: Ball spin adjustment slider bar not working in camera panel when using right arrow key

Fix: Possible error in spin calculation causing excessive spin rates

April 7 1:00 pm

Possible 20% increase on some items (like The ProTee VX from Holland and Cameras from China) due to Trump taxes coming up.

April 4 5:20 pm

CP 64 update 10.3.1.7

Fix: Ball spin adjustment slider bar not working in VisTrak Video panel

Fix: Possible error in spin calculation

April 3 3:00 pm

CP 64 update 10.3.1.6

Fix: Ball speed / carry adjust slider not working in camera panel

Correction to club face angle calculations when using club top edge white strips

April 2 8:30 am

New curved screens and curved screen enclosures with pre-cut and curved frame tubing

April 1 12:30 pm

CP 64 update 10.3.1.5

Correction to club face angle calculations when using club top edge white strips

March 31 11:00 am

New GSA Golf enclosure parts selection

New GSA Golf Pro enclosures

GSA Golf Pro enclosure framing

Click above images for details and pricing

March 29 11:00 am

New GSA Golf enclosure panels

New GSA Golf screen bumbers

New GSA Golf self standing enclosure range coming tomorrow.

with or without screens - with or without flooring

March 28 1:30 pm

CP 64 update 10.3.1.4

Vast improvements to calculated spin.

Almost identical to measured spin now.

Measured and calculated spin comparison data

Shot Video 187 – GC3 got: 6441 – SCX 6329 rpm - dif: 112 rpm

Shot Video 186 – GC3 got: 5672 – SCX 5809 rpm - dif: 137 rpm

Shot Video 185 – GC3 got: 5976 – SCX 6115 rpm - dif: 139 rpm

Based on the above tests results, we are concluding that there is no significant difference

between measured and calculated ball spin measurements

March 14 10:10 am

CP 64 update 10.2.9.7

New ix camera Swing Capture updates

Foot switch opreation now added for those that wish to manually start and stop the swing capture cameras

Note that the foot switch is assigned to the keyboard's Space bar

Click above image for more details

February 27 3:00 pm

Free wedge stickers now available:

The bright wedge issue:

Currently, it cannot be guaranteed that small chips with bright faced wedges will be detected.

If the issue persists, you'll have to use dark colored wedges or apply the new supplied sticky back matte black stickers to the wedge face.

Above image showing how the wedge looks when the wedge black sticker is applied

Just email us with your address for your free black wedge stickers pack if you didn't already receive them.

February 2712:45 pm

CP 64 update 10.2.8.9

1. Full screen mode

You can now run the CP in full screen mode instead of it being in a window.

Select full screen ON/OFF in the Setup panel (bottom mid screen)

2. Improved club face detection when striking the ball on the club's toe or heel

![]()

![]()

Click above for all your accessory requirements

Similar product market overview

![]()

Factory

Based in Naples, Florida,

all GSA Golf products are meticulously assembled and tested by hand to meet the highest industry standards

![]()

![]()

GSA Golf golf simulator components and kits

CX and Vistrak system components can be used to build the complete GSA Golf golf simulator camera tracking system

at a far lower price than the ready made system prices

Click above to read more about GSA Golf components and kits

![]()

The GSA Golf camera tracking software is available to

all OEM golf simulator manufacturers

and/or DIY enthusiasts for just

$ 299.00

Just purchase your own cameras and lighting

Click above image to read more

![]()

GSA Golf Investment and Reseller Opportunities

![]()

Recent customer comments

Hi Martin, I just wanted to drop you a note to say how amazing the new VisTrak camera is.

I am still playing around with the settings and learning but the video capture and being able to see the frame by frame impact is awesome!

I also really like the way you show the ball ready/playback buttons as an overlay on the TGC.

The best part of my day is going to the tech page and seeing your latest updates - keep up the good work!

Richard L. Illinois 12/17/2020

![]()

Hi Martin- I wanted to let you know how much I appreciate your efforts.

I could have bought any of the expensive and well-known golf simulators, but I’m glad I ultimately took the chance and bought your products.

It wasn’t an easy decision, as it takes a leap of faith to take the road less traveled, but it has made all the difference.

I love that your products are not perfect (no one's are) but that you strive for perfection while pushing innovation.

You’re clearly never satisfied. As soon as you develop a new software feature, or build a new camera system, you're immediately back at it working on the next iteration.

You’re a true inventor and engineer. Almost every day I download the latest beta and see how it enhances the simulation.

It's like Christmas morning everyday.

Sometimes there’s a marked improvement. Sometimes the new feature “breaks” something else.

But over days and weeks, I feel how the collective innovations are improving the overall experience.

Your products aren’t for everyone but they are a clear alternative to the high-margin corporate products that have an arm's length association with their user base.

Buying a GSA product is buying into you and becoming part of your user community.

You listen, you care, and you explore. I know many of us appreciate it but perhaps not enough of us say thanks.

Martin, thank you for an enjoyable and rewarding journey with your products in 2020.

You’ve made a COVID 19 year more endurable.

Eric P. Burien, WA 12/25/2020

![]()

Matt P. 1/15/2021

Hello Martin, I have had 2 weeks of excellent play and stability in Eagle Mode! This has been very enjoyable! Matt T.

![]()

Matt T. 1/14/2021

Hi Martin, I see your daily updates on the Tech News page and I just want to say thank you for all your hard work and dedication.

Your passion for golf and engineering clearly shows and thank you!

![]()

Mike B. 05/03/2021

Thanks Martin……..

I appreciate the excellent customer service and fair pricing! And the very informative website!

Have a great day!

Mike.

![]()

Click above button to read more...

![]()

Technical Support

![]()

Martin Gardiner

Founder of GSA Golf

These days, when I'm not developing golf simulators, you'll find me in my keyboard music studio

Hi! I'm Martin Paul Gardiner

Electronics and software development engineer and founder of GSA Golf

Regularly check out my tech news page for all our latest developments and free updates

if you have any questions

please feel free to contact me personally anytime from M to F 10am to 3pm US ET

Currently looking into integrating AI technology into GSA Golf tracking systems

![]()

Contact us

![]()

Business opportunities with GSA Golf

Enjoy huge earnings and great markups by using our cameras and software

for your system installations or just offering any of our products for direct sale.

![]()

Launch Monitors

VisTrak hi-speed camera Launch Monitors from $ 1,999.00

Click above images to read more...

![]()

PROTEE VX

Currently the world's most advanced hi-speed tracking system

$ 6,499.00

This ceiling mounted, camera based system accurately measures club and ball data

without the need for specialty balls or marked clubs !

Click above images to read more...

![]()

![]()